In the field of industrial automation, custom automation equipment has become an ideal choice for many manufacturing enterprises to enhance production efficiency and optimize process flows due to its tailored nature. Therefore, understanding the key components of custom automation equipment is crucial. Below, we introduce the components of custom automation equipment. Let's take a look.

What Components Make Up Custom Automated Machinery?

1. Sensors

Sensors are indispensable components in custom automation equipment. They monitor positional changes of objects and detect parameters like mass and size through various sensor types. Sensor applications ensure equipment adapts to diverse production demands, forming the foundation of automated control. Whether photoelectric or pressure sensors, each serves a vital role.

2. Servo Motors

Servo motors achieve precise adjustments to equipment components by accurately controlling current and voltage. Primarily used for precise positioning on automated assembly lines, their high precision and response speed make them core drive components in automation systems.

3. Electrical Control System

The electrical control system serves as the command center for non-standard automated equipment. By integrating various sensors and actuators, it manages the equipment's movements and operational states.

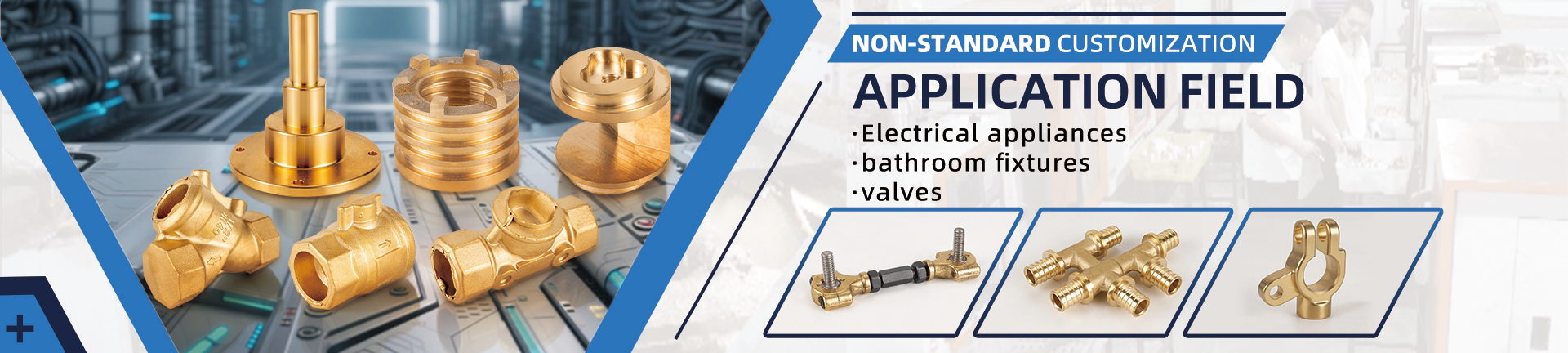

4. Mechanical Components

Mechanical components—including gears, drive shafts, reducers, and guide rails—enable motion control and positioning across different equipment sections. They form the foundation of mechanical transmission systems, supporting precise operations and stable performance.

5. Pneumatic Components

Pneumatic components—including air preparation units, solenoid valves, and cylinders—are widely used in production line control processes due to their rapid response and low maintenance requirements. They are indispensable in automation equipment, particularly excelling in operations like switching and clamping.

6. Vacuum Equipment

Vacuum equipment, such as vacuum pumps and suction cups, rapidly adsorbs and evacuates gases, creating a stable working environment for custom automation systems.

The coordinated operation of these critical components forms the foundation for efficient and accurate production in custom automation equipment. Through meticulous design and precise assembly, these parts deliver significant productivity gains for manufacturing, conserving human resources and reducing production costs.

Purchase Steeloten and build beautiful websiteWhy We are Best in Industry

Tel:+86-13184373818

Email:zerodegreeheart@gmail.com

Address:industrial Cluster Area,Qinggang Town,Yuhuan City,Zhejiang Province